Subscribe now and choose from over 30 free gifts worth up to £49 - Plus get £25 to spend in our shop

Managed to crash this morning, seriously distorted by built-in mech hanger plus opened up the drop-out of my 456Ti - luckily the XTR mech took most of the impact... double bugger.

Never mind the scarred forearm and highly bruised thigh.

Oh yes, and the chap I managed to clip - probable broken bones in wrist/thumb/hand etc and big bleeding across both legs - sorry Colin 😳

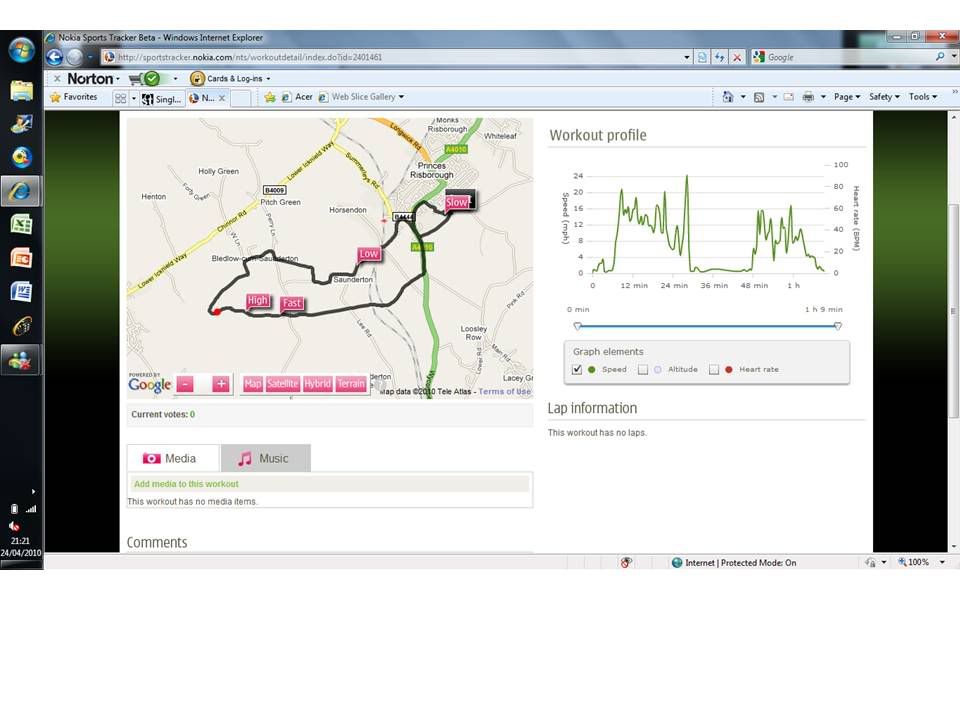

And according to my GPS, at 28.5 mph!

Any clues/ideas on realigning said hanger and closing up the drop-out?

Ti needs to be worked cold so just bent it back [b]carefully[/b] with a big adjustable. Then take it to an LBS with a gear hanger alignment tool to make sure it's straight.

Wiggle do a decent gear hanger tool for £25 approx - basic but does the job

Dropped it in to my LBS, the mechanic had a look and will call a frame-builder he knows for advice tomorrow.

I'm less worried about the bent hanger, than the opened-up drop out.

theres a guy on here who opened up the dropout on a steel 456, I'm sure he'll be arround in a bit, maybe start a new thread with "bent 456 dropout" in the title?

A remarkable photo, normally when trying to bend / distort titanium (alloy 6/4 etc) that much when cold it just snaps. So it is possible that it is commercially pure (the dropout that is, not the tubes).

It is possible to heat titanium to reshape it, as long as you stay well below 800 degrees celsius. Titanium will readily combine with nitrogen at 800 degrees c and above.

There is the problem of forming an alpha case on the metal (crystaline structure) when heated, and titanium does not look pretty after heating in air (or any active gas). Therefore a possible way to heat it is in the shield gas (argon) of a TIG torch.

It is therefore:

1 Try to bend back cold and it might snap and it will not look great.

Hold the gear hanger very firmly in a vice and pull the frame around till it looks OK.

2 Try heating it with TIG arc in argon shielding (if you can find anyone to do it) not going to be easy, or look pretty.

3 Get the damaged part only removed and a fabricated replacement gear hanger welded on, again not going to be easy finding someone to do it.

Ceeway might know someone to do it.

Ask On-one for advice?

First up - call On-one. They might do a crash replacement deal?

I got my oldman (has his own company and workshop) to fix a badly bent alloy stay for me once. He staightened it, kept it at the right temperature and annealed it for me.

Top fella likes. If you like I can give him a call and ask advice?

Single speed it (ti)?

or

Alfine?

on-one have been rung and sent a pic, hope to hear back from them tomorrow with their opinion

How the hell did you crash and do that much damage to someone else?

Macavity is pretty much spot on.

If its CP Ti (DEFO ring Brant to find out the spec) you could be in luck, its bends OK cold. 3/2.5 will also bend cold. Do be carefull though!

6/4 *can* be bent cold, but you need large bend rads (which you cant control in this instance) and there is always a chance it will crack (acceptable risk on a "low" value bracket, but not on a frame).

A pre-bend anneal (730 deg C for 1/2 hour) will improve cold bending no end. But how you heat treat the frame (bare in mind the problems associated with heating Titanium) I dont know.

You could have the drop-out replaced, but you're stuck with the usual problems with finding a fabricator that can do it.

Gutted, hope your mates ok and you get your bike fixed, I think most of us have been in that locked bars situation when bombing down hill racing friends!

theres a guy on here who opened up the dropout on a steel 456, I'm sure he'll be arround in a bit, maybe start a new thread with "bent 456 dropout" in the title?

That's probably me. 🙂 Although it was an 853 Inbred. And it was a LOT worse than that. Mine was so bad the hanger locked the cassette solid!

Firstly, you've got nothing to loose by trying to bend it back. It's not useable as it is, so you might as well try.

Secondly - TAKE YOUR TIME WITH IT!!!! Don't start hitting it with a hammer! If it's going badly, WALK AWAY and try tomorrow!

I stripped the bike down so I could put the frame in a vice, then firstly got the hanger roughly straight. The thing is, it might not want to bend back in the same place it bent in at, if you see what I mean, so you have to be careful to clamp the hanger in the vice, and use the edges of the jaws to get it to bend back in the right place. It's NO USE trying to do it any other way, you risk having an 'S' bend in your hanger!! Seriously!

Clamp the hanger in a the vice, use the frame as leverage.

Then, when it's roughly straight, you need to get the dropout closed up. Again, it might not want to bend back in the same place, so you need to ensure the dropout remanins 'dropout shaped' and not teardrop shaped!

I got an old hub axle and a couple of nuts, which I clamped into the dropout, to use as a 'former' if you like. Then I clamped some molegrips on the dropout, so the jaws were on top and underneath the hanger (Handle pointing backwards) and then turned the frame upside down and sat on it, so I could pull the dropout towards me round the axle, and see what was happening. I also screwed a bolt into the mech thread, so I wouldn't close the hole up as I was bending, or from the molegrips

Then I used a hanger alignment tool to get it spot on. You can't guess this, just buy the tool, IMO!

End result, burrs filed off, wire brushed clean.

[img]  [/img]

[/img]

That was 3 years ago now and it's been fine ever since. 🙂

Peter, thanks for the effort.

Mine also had wedged into the cassette, and I opened it up a bit at the time so I could SS it to get home...

I'm off down my LBS later today, where myself and the mechanic (Andy from above) will have a read of all the posts (and speak with On One) before attempting a fix.

and speak with On One

Brant (at the time) wasn't a great deal of help, TBH. He just said, "Well you might as well give it a go!"

A couple of times after I fixed it he gave people in the same situation my email address......

It'll bend back!

Many years ago I had one of the Raleigh SPD Ti frames (the fully Ti welded ones not the glued together TI and steel versions) and I managed to stuff the mech into the back wheel bending the gear hanger in the process.

Dropped the bike of at Roberts and a few days later it was all sorted, they simply put a big tool on it and bent it back.

Steel dropouts are malleable at room temperature and are relatively easy to deal with.

Titanium alloys (alpha beta alloys) are not so malleable at room temperature.

However just on the basis of looking at the picture the titanium drop out appears to be malleable at room temp. So it must be Commercialy Pure (CP alpha structure).

So, it probably will be possible to straighten it out at low temperature.

http://www.alloysinternational.com/commercially_pure_titanium.htm

"Commercially Pure Titanium contains the lowest oxygen and iron levels, producing the most formable grade of material."

"Commercially pure titanium is stable for use in the temperature range up

to approximately 300ûC due to its specific strength, creep resistance, and

other properties."

"Low temperature characteristics

Neither commercially pure titanium nor titanium alloys become brittle

even at extremely low temperatures." Titanium alloys are just not so malleable at low temperatures.

Riding like a knob, and trying to get between 2 riders on a fast down...

Was this a race? I wouldn't be too impressed if I was the guy with the broken wrist if not.

Std practice in LBS is to use the hole in the end of an adj spanner to bend the dropout back in place. I uses the jaws to straighten them also - it's not diffcult to align it by eye and check with a rear mech IMO.

wot grum said - even if you have to buy a new frame vs having a broken hand and future arthritis etc then you'll have got off very lightly.

Having said that - give Enigma a ring - they build Ti frames in the UK and can probably advise on fixing them/actually fix it - they'll weld a new drop out on for you if necessary.

"Std practice"

Even for steel dropouts it is still easier and neater to hold the dropout in a vice and twist/turn the frame about to do most of the work. Then fine tune with the right tools. Dropout alignment gearhanger alignment.

Seven Cycles have some good info on titanium:

grum and wwaswas

Don't disagree, I was (and am) more bothered about knocking the chap (Colin, who've I've emailed but probably understandably he's not come back to me) off than the frame damage.

Worse case bike-wise, in the short-term I'll just build back up my steel 456 - longer-term probably a carbon 456.

Except the 20" has just gone out of stock - will my luck not change?

Carbon one should be about free ie crash replacement at aprox 50% 😀

...on another note your right out the back of where im working fancy showing me some roots when you sort the bike out ?

Discussions have taken place with On One, who also spoke with Mark Lynskey.

Attempt to bend it cold, if it fails On One will ship it to Lynskey for a new drop-out for the cost of the postage. I'm happy with that, so now down to the LBS via the coffee shop!

Will report back.

sounds like a result.

I'm bloody glad I don't ride with you.

>I'm bloody glad I don't ride with you.

+ lots 🙂

For those that can't accept that shit happens, take up sofa surfing, don't carry hot drinks and stay away from stairs/ladders etc.

Otherwise.

Just spent an hour or so at my LBS, and we managed to get it back into a usable position with the drop-out almost closed up. Lots of patience, tools, vice, work stand and good luck it seems. And of course Andy the mechanic, thanks to Buckingham Bikes.

So rebuild it this afternoon and see how it rides.

For those that can't accept that shit happens, take up sofa surfing, don't carry hot drinks and stay away from stairs/ladders etc.

From contrition to chippyness in a very short space of time.

Should I be worried about having entered the 4 lap Gorrick at the weekend and your proximity to me at the start!?

Glad you got it sorted, good service from On-One.

Nick - only when you lap me!

Attempt to bend it cold, if it fails On One will ship it to Lynskey for a new drop-out for the cost of the postage. I'm happy with that, so now down to the LBS via the coffee shop!

I don't think you can grumble at that. Sounds very fair to everyone to me. 🙂

Now rebulit and running fine.

Drop-out not fully closed up, but I'll monitor it and if it gives me problems ship it off to Lynskey for a new drop-out to be welded-on.

Thanks to all for your help.

Update.

Wasn't fine. Couldn't get the 'axle-hole' below 10mm...

So sent to On One, who've sent it on to Lynskey.

3 months later it came back, via On One, including a few weeks in East Midlands airport customs...

Fantastic job, frame re-finished and I believe a new drive-side triangle.

£100 all in - so very happy.

Next time though I'd probably just send it to a UK-based company with the skills - Enigma maybe ( http://www.enigmabikes.com/) - so hopefully I'd get it back a bit quicker.